Compare LIMS Software for CMT & Geotechnical Labs | Aldoa

See how Aldoa’s LIMS stacks up against generic and industry LIMS. Compare features like ASTM support, compliance, field workflows, and audit...

Atterberg Limits testing plays a foundational role in geotechnical engineering. Liquid Limit (LL), Plastic Limit (PL), and Plasticity Index (PI) values directly influence soil classification, shrink swell potential, settlement analysis, and material suitability decisions.

Most geotechnical and Construction Materials Testing (CMT) labs perform ASTM D4318 early in a project lifecycle. Because these values flow into boring logs, laboratory reports, and final geotechnical recommendations, accuracy and documentation consistency are critical.

This guide explains what ASTM D4318 measures, how Liquid Limit and Plastic Limit tests are performed, common calculation and documentation challenges, and how modern labs streamline Atterberg Limits workflows using Aldoa without spreadsheets or rework.

ASTM D4318 defines the procedures for determining a soil’s Liquid Limit (LL), Plastic Limit (PL), and Plasticity Index (PI). These values are essential for:

Most geotechnical projects require Atterberg Limits early in design. Because LL and PL directly influence boring logs, laboratory reports, and geotechnical recommendations, accuracy and documentation matter.

Because LL and PL values directly influence engineering decisions and final reports, reliable testing and traceable documentation are essential throughout the project.

Liquid Limit (LL): The moisture content at which a soil transitions from a plastic to a liquid state.

Plastic Limit (PL): The moisture content at which a soil begins to crumble when rolled into threads.

Plasticity Index (PI): The numerical difference between Liquid Limit and Plastic Limit (PI = LL − PL). PI is one of the most important indicators of soil behavior.

Soils with higher PI values tend to be more compressible, moisture sensitive, and susceptible to shrink swell. Low PI soils behave more like granular or non plastic materials. Because PI is derived from two separate tests, consistent calculations and traceability are essential in both lab documentation and final geotechnical reporting.

These values directly influence:

Geotechnical engineers rely on LL, PL, and PI to:

This means errors or inconsistent documentation slow down design, cause confusion in field operations, and create audit risks. Because these values flow directly into boring logs, lab reports, and design recommendations, even small documentation errors can create downstream delays and rework.

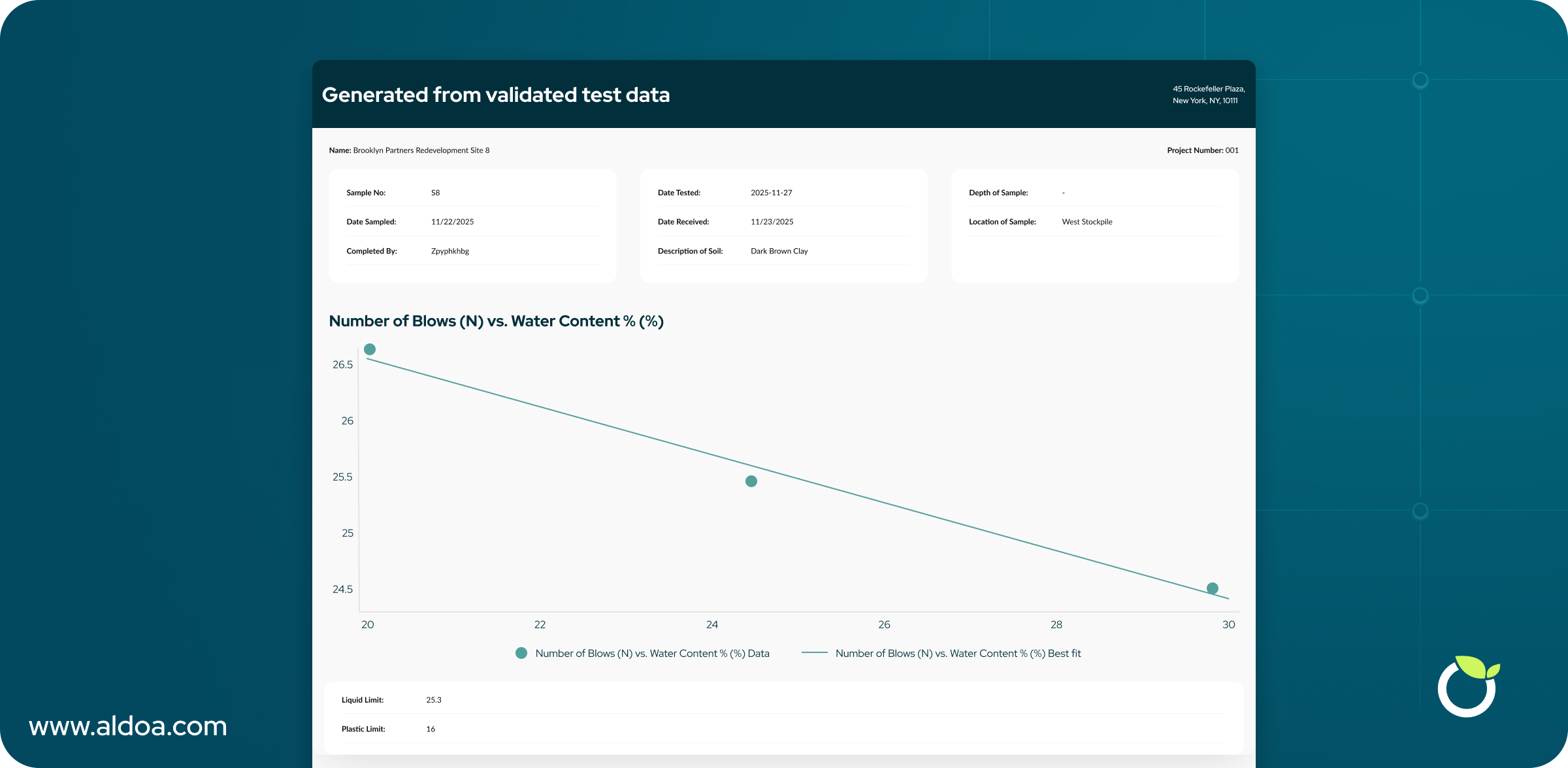

Performed using fall cone or Casagrande apparatus.

You record:

Objective: determine the water content at the LL point.

These values feed into classification and design workflows.

While the test itself is straightforward, managing multiple samples, calculations, and documentation across projects is where most labs lose time.

Many labs still rely on disconnected tools and manual processes to run ASTM D4318, which creates delays and inconsistency across projects.

Multiple file versions and varying formulas often lead to inconsistent Plasticity Index calculations and extra verification work.

Sample photos, depth information, and boring log references are frequently stored separately from lab results, making traceability difficult.

Without a centralized lab management system, these disconnected workflows slow reporting, complicate reviews, and create unnecessary rework. Aldoa addresses these challenges by connecting field and lab data in a single, standardized platform.

Field technicians create a sample directly in Aldoa, capturing:

Sample IDs flow directly into project logs, ensuring the lab receives complete context.

Technicians see incoming samples organized by:

Supervisors can plan LL and PL testing without guesswork.

Standardized digital forms ensure every technician uses the same process.

Aldoa automatically computes:

Internal checks flag possible mistakes before approval.

Managers can:

Every action is logged for QA and DOT audits.

Once test results are approved, Aldoa automatically updates all downstream documentation without manual re-entry. Liquid Limit, Plastic Limit, and Plasticity Index values flow directly into soil classifications, boring logs, and final geotechnical summaries.

By automating technical report generation, labs eliminate duplicate data entry, reduce review cycles, and ensure Atterberg Limits results remain consistent from the original sample through final project deliverables.

LL is the moisture at which soil behaves like a liquid.

PL is the moisture at which soil crumbles when rolled.

PI = LL - PL.

Casagrande cup or fall cone; both are allowed.

Yes. PI influences shrink swell behavior, compressibility, and material suitability.

Yes. Technicians can record Casagrande or fall cone data in standardized digital worksheets.

See Atterberg Limits Workflow Demo: Schedule Demo

Atterberg Limits testing is often performed alongside other laboratory and field tests to fully characterize soil and aggregate behavior. Geotechnical and CMT labs commonly run ASTM D4318 in combination with the following workflows:

ASTM D2216 – Moisture Content Used to determine the water content of soil samples, which directly affects Liquid Limit, Plastic Limit, and Plasticity Index calculations.

ASTM D1557 – Proctor Compaction Helps evaluate soil compaction characteristics and density, often interpreted alongside Atterberg Limits when assessing material suitability and performance.

ASTM C136 – Sieve Analysis Measures particle size distribution and gradation, frequently paired with Atterberg Limits for soil classification and design decisions.

These tests work together to inform soil classification, engineering recommendations, and final geotechnical reporting.

LL, PL, and PI testing should be accurate, consistent, and fast. Aldoa's construction materials testing software unifies field sampling, lab calculations, PI generation, and boring log reporting into a single connected workflow. This reduces errors, speeds up turnaround, and improves visibility across geotechnical teams.

Aldoa gives labs and field teams a modern way to run ASTM D4318 without spreadsheets, manual transcription, or outdated legacy systems.

See how Aldoa’s LIMS stacks up against generic and industry LIMS. Compare features like ASTM support, compliance, field workflows, and audit...

Explore the best geotechnical and construction materials testing (CMT) software. Compare Aldoa vs. Bentley gINT, MetaField, and Agile Frameworks....

Learn ASTM D2216 soil moisture testing step-by-step. See formula, reporting requirements, and how Aldoa simplifies compliance with customizable forms.

Purpose-built for consultants and engineers. The easy-to-use system helps your team complete projects on time, stay within budget, and increase profitability.