Aldoa and ForneyVault Integration: Connecting Field and Lab Data for CMT Efficiency

Aldoa announces its integration with ForneyVault, creating a seamless data flow between field collection, lab testing, and reporting for construction...

Concrete quality control is the backbone of safe, durable, and compliant construction. From field sampling to cylinder breaks and final reporting, every step of the concrete testing process must be executed accurately, documented thoroughly, and reviewed consistently.

Yet many concrete QA/QC teams still rely on paper forms, spreadsheets, and disconnected systems that introduce errors, slow turnaround times, and increase compliance risk.

Modern concrete quality control software solves these challenges by digitizing workflows, enforcing QA/QC standards, and connecting test data across field, lab, and reporting systems.

This guide explains what concrete quality control software is, why it matters, key QA/QC capabilities to look for, and how modern platforms like Aldoa integrate with testing machines and lab systems to deliver reliable, audit-ready results.

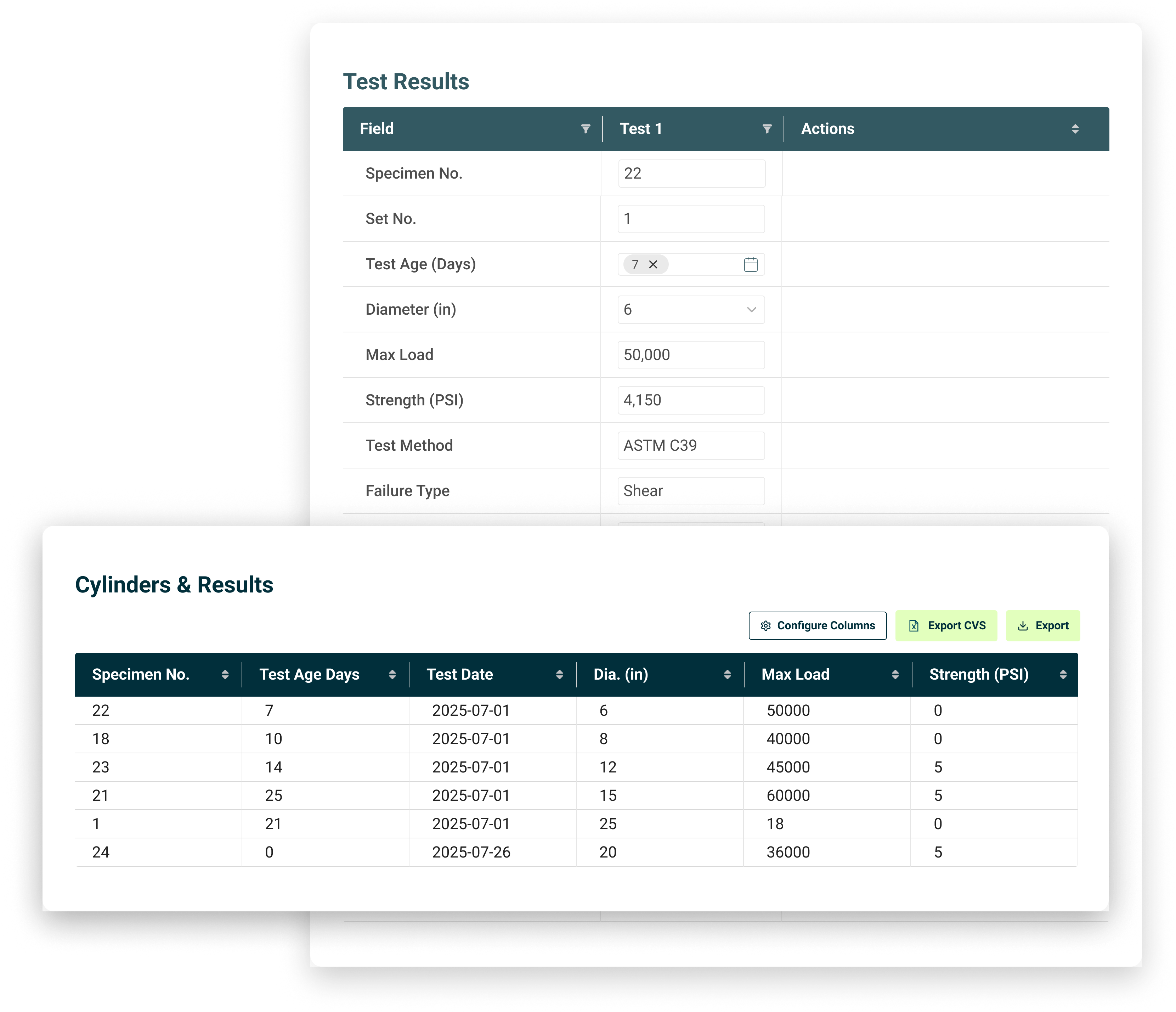

Example of ASTM C78 flexural strength test results captured and managed inside concrete quality control software.

Concrete quality control software is a digital system used by construction materials testing (CMT) labs, concrete producers, and QA/QC teams to manage concrete testing data, workflows, and compliance documentation.

At its core, concrete QC software helps teams:

Unlike basic spreadsheets or standalone machine software, modern concrete QA/QC platforms connect people, processes, and data across the entire testing lifecycle.

Concrete testing machines generate critical strength data, but QA/QC does not start or end at the machine.

A complete concrete quality control process includes:

Without software that enforces these steps, even accurate machine data can become incomplete, unverifiable, or non-compliant.

That is why leading QA/QC teams pair machine-level data integrity tools with workflow-focused QA/QC software.

Despite the importance of QA/QC, many teams struggle with execution.

Manual Data Collection: Paper field tickets and handwritten cylinder tags lead to missing information, transcription errors, and delays.

Disconnected Systems: Field data, lab results, and reports live in separate tools, making traceability difficult and reviews time-consuming.

Inconsistent QA/QC Processes: Without standardized digital workflows, QA/QC checks depend on individual habits rather than enforced rules.

Audit and Compliance Risk: DOTs, owners, and accreditation bodies require clear documentation, approvals, and historical records that are difficult to assemble manually.

Not all concrete QC software is the same. The most effective platforms combine data integrity with workflow control.

Concrete QA/QC starts in the field. Modern software replaces paper forms with mobile-friendly digital workflows that ensure required data is captured consistently.

This reduces errors at the source and ensures lab teams receive complete, reliable information.

Every cylinder must be traceable from pour to break.

Concrete quality control software should provide:

This prevents missed breaks, misplaced samples, and undocumented handling.

True QA/QC happens before reports go out the door.

Modern platforms embed QA/QC directly into workflows by enabling:

This ensures results are defensible and consistently reviewed.

Testing machines produce authoritative strength data, but that data must be connected to the broader QA/QC process.

Leading concrete quality control platforms integrate with machine-level systems such as ForneyVault to automatically capture break data and link it to:

This eliminates manual re-entry while preserving data integrity.

Concrete QC software should generate client-ready reports directly from approved data.

Key reporting capabilities include:

Reports should be reproducible, traceable, and audit-ready at any time.

Aldoa is a modern concrete quality control and QA/QC platform designed for CMT labs and geotechnical firms that need more than isolated machine data.

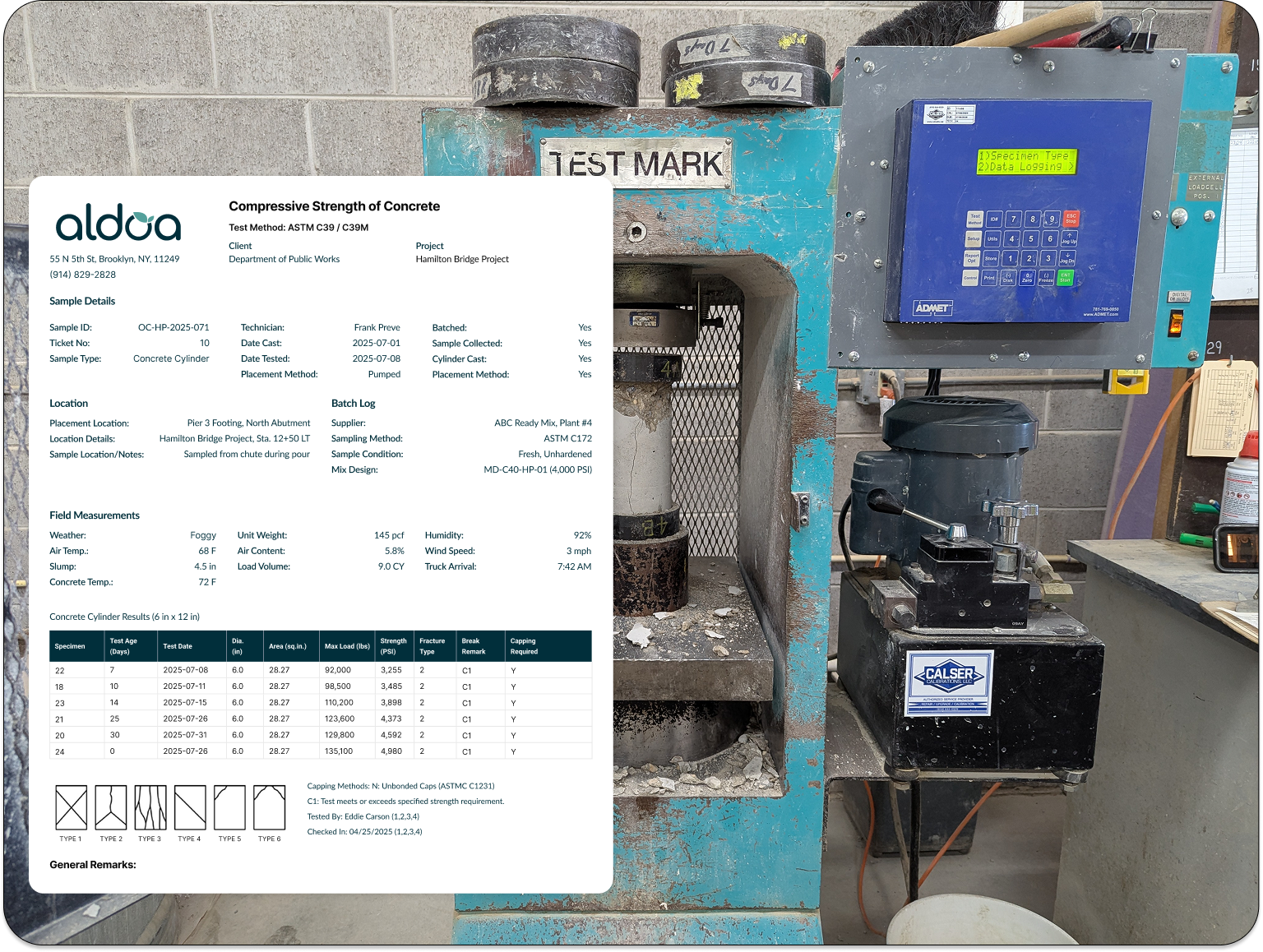

Automated ASTM C39 concrete compressive strength results captured from lab equipment and reported through Aldoa’s concrete QA/QC software.

Aldoa connects:

By integrating with concrete testing machines while managing the full QA/QC workflow, Aldoa ensures that every test result is complete, traceable, and defensible.

QA/QC is enforced inside the process, not added as a manual step at the end.

Concrete QA/QC is not just about passing tests. It is about delivering trust.

Modern concrete quality control software helps teams:

By combining machine-level data integrity with workflow-driven QA/QC, teams can meet today’s compliance requirements while preparing for tomorrow’s projects.

When evaluating concrete QC solutions, look beyond individual features and focus on how well the system supports the entire QA/QC lifecycle.

The right platform should:

Aldoa delivers all of this in one connected platform built specifically for concrete testing and QA/QC teams.

See how Aldoa integrates concrete QA/QC workflows from field sampling to machine data and final reporting. Schedule a demo to learn more.

Aldoa announces its integration with ForneyVault, creating a seamless data flow between field collection, lab testing, and reporting for construction...

Compare the best construction materials testing (CMT) software in 2026. See how Aldoa, MetaField, and QESTLab stack up for ASTM compliance, reporting...

Discover the top challenges facing consulting & engineering firms and how technology, AI, and automation can boost efficiency and profitability. Read...

Purpose-built for consultants and engineers. The easy-to-use system helps your team complete projects on time, stay within budget, and increase profitability.