The Evolution and Digital Future of ASTM Geotechnical Standards

Explore the evolution of ASTM geotechnical standards and how digital workflows, LIMS software, and automation are shaping the future of ASTM...

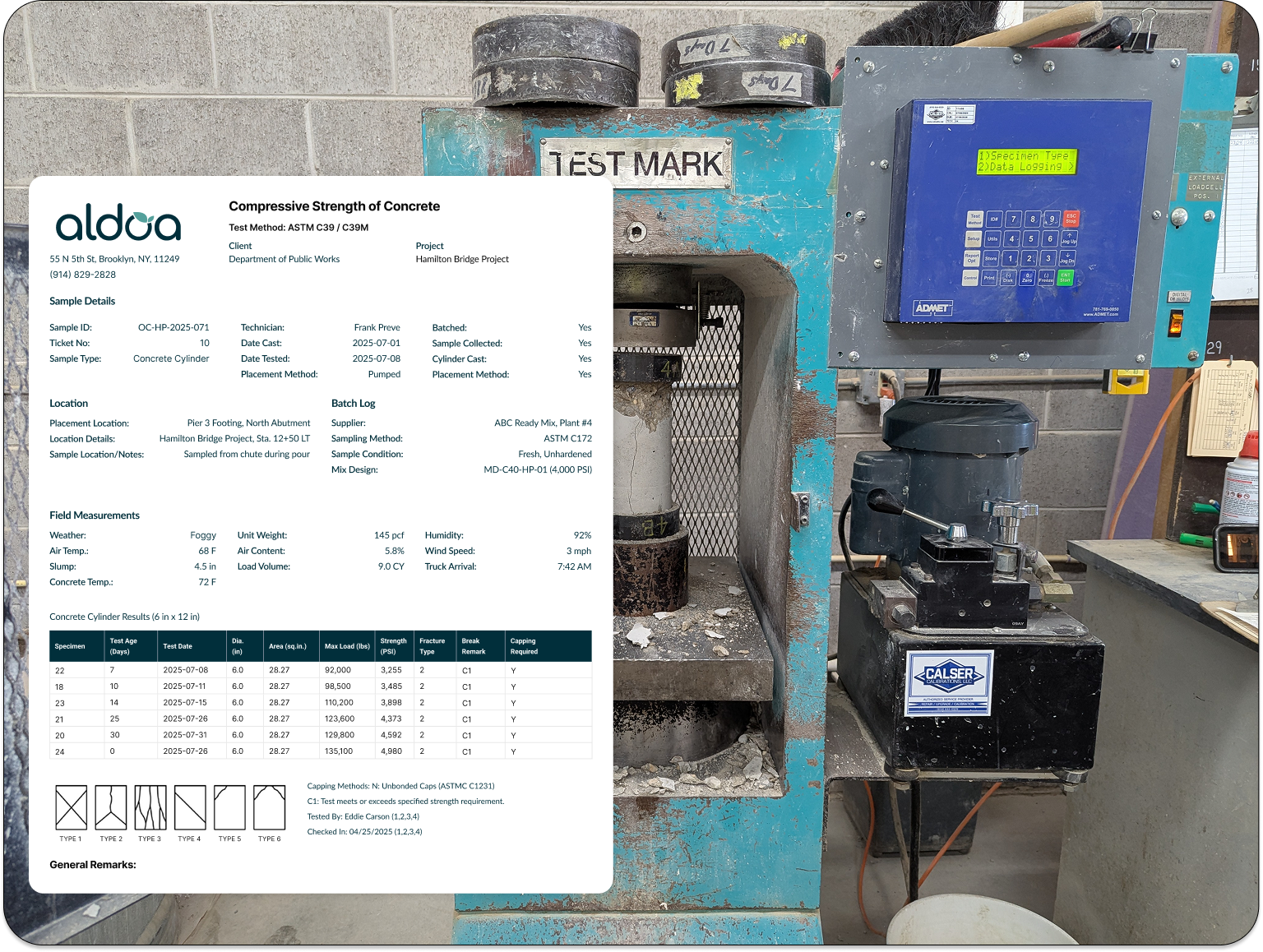

Concrete compressive strength testing is one of the highest volume responsibilities for construction materials testing laboratories. Every commercial building, roadway, bridge, utility structure, and public infrastructure project depends on accurate concrete cylinder testing to verify that design strengths have been achieved.

ASTM C39 defines the standard test method for compressive strength of cylindrical concrete specimens. The procedure is simple in concept, yet the workflow behind it is often slow, error prone, and difficult to standardize. Most labs still rely on manual entry, clipboard notes, spreadsheets, and disconnected break machine systems that make reporting inefficient.

Many of these challenges stem from relying on disconnected tools that were never designed specifically for concrete testing workflows. Modern concrete testing software replaces paper tickets, spreadsheets, and manual report formatting with a single, connected platform built for field and lab teams.

This article explains the C39 procedure, identifies common workflow challenges, and shows how Aldoa helps labs eliminate paperwork, improve accuracy, and accelerate turnaround times.

ASTM C39 covers the determination of compressive strength of cylindrical concrete specimens prepared and cured under standardized conditions. The test typically uses 4 by 8 inch or 6 by 12 inch cylinders with known ages such as 7 days, 14 days, 28 days, or any project specific age.

The procedure requires:

Test results include:

These values support decisions about formwork removal, post tensioning, structural acceptance, and overall quality assurance on construction sites. Since concrete strength results have direct financial and safety implications, accuracy and standardization are essential.

ASTM C39 compressive strength testing of cylindrical concrete specimens

Although the test method is well understood, the workflow behind it often creates bottlenecks for labs and engineering firms. Many rely on handwritten sheets near the break machine, re entry into spreadsheets, or Word templates that vary from technician to technician.

These issues often appear:

Technicians write the maximum load and break type by hand, then re enter it later. This increases the chance of incomplete notes or incorrect data entry.

Field technicians create samples on paper tickets or basic spreadsheets. The lab often does not receive complete sample information until cylinders arrive. Missing sample IDs cause delays.

Different labs use varying machines. Some produce digital outputs. Others require manual reading of gauges. Few labs have systems that capture machine data directly into a reporting platform.

Even after the test is complete, many labs require extra steps to format a professional report. Copying values from spreadsheets into PDF templates takes time.

Technicians use different worksheet versions, which creates issues during audits and makes results harder to review.

These workflow gaps increase risk, reduce throughput, and often frustrate clients who expect real time reporting. Aldoa solves these problems with a connected platform that supports the entire lifecycle of a concrete sample.

Aldoa replaces fragmented processes with a single platform that integrates field collection, sample tracking, break testing, and reporting. This creates a smooth and traceable workflow that benefits technicians, supervisors, and clients.

Below is the full workflow modernized with Aldoa.

The process begins in the field when concrete cylinders are taken. Technicians log each specimen directly in Aldoa using mobile friendly forms. They can capture:

Cylinders receive unique IDs or barcodes. Because the field and lab share the same platform, the lab knows exactly what samples are coming and when they were collected.

Field teams no longer fill out paper tickets that may get lost or damaged. Aldoa ensures a clean and traceable sample chain.

When cylinders arrive at the lab, technicians scan or select the sample IDs and place them in curing rooms. Aldoa stores:

Supervisors can view upcoming break schedules and plan daily workloads with accuracy.

On the day of the break test, technicians perform the ASTM C39 procedure. Aldoa supports several entry methods depending on the lab and machine type.

If the lab uses ForneyVault enabled equipment, Aldoa can integrate seamlessly. Machine data appears automatically in the correct Aldoa test record. This captures:

This removes all manual transcription.

Technicians enter maximum load and break type directly into Aldoa’s standardized C39 form. Real time calculations convert loads to psi or MPa.

Aldoa includes drop downs for break types that match ASTM language. This reduces ambiguity and ensures consistent documentation.

Some labs use a combination of automated machine output and technician classification. Aldoa supports any combination without requiring extra templates or spreadsheets.

Aldoa performs the following automatically:

Technicians see results immediately. Supervisors see the status across all breaks in progress.

Before a report is published, supervisors can review:

Aldoa keeps an audit trail that captures edits, approvals, and reviewer notes. This helps maintain compliance with ASTM C39, ACI requirements, and internal quality programs.

Once the break test is approved, Aldoa generates a clean, professional concrete strength report. Reports include:

The formatting is consistent across projects, offices, and technicians. This improves the client experience and reduces time spent on corrections or clarifications.

Technicians can capture data at the point of sampling with standardized digital forms, improving clarity and traceability.

Machine data populates automatically into Aldoa. This eliminates transcription errors and improves speed.

All technicians follow the same method. This supports training, compliance, and operational consistency.

Aldoa performs all C39 strength calculations in real time.

Supervisors can view cure ages, upcoming breaks, and workload distribution across teams.

Reports are generated instantly and follow a consistent branded format.

Aldoa keeps all test data, edits, signatures, and notes in one place for easy auditing.

Looking for a complete concrete testing workflow? See how Aldoa supports field sampling, cylinder tracking, compressive strength testing, and ASTM-compliant reporting in one connected platform. Explore Aldoa’s Concrete Testing Software.

The goal of modern concrete testing software is not just digitization, but operational clarity across field and lab teams.

Spreadsheets require manual data entry and formula management. Aldoa manages the entire workflow from field to report without spreadsheets or manual formatting.

Paper notes slow everything down and introduce risk. Aldoa centralizes everything in a digital record that is never misplaced.

MetaField provides digital forms, yet customers experience slower lab workflows and generic PDF templates. Aldoa provides a simpler interface, faster reporting, and stronger integration between field and lab.

SpectraQEST is powerful but complex. Aldoa offers an easier, more modern alternative that lab technicians can learn quickly without sacrificing quality or compliance.

Maakil Group, a firm experienced with both Aldoa and MetaField, shared that Aldoa’s workflow improved their cylinder break reporting by reducing manual entry steps, improving visibility across technicians, and cutting report turnaround time significantly.

Clients noticed more consistent reporting and faster delivery. Supervisors benefited from clear audit trails and easier review.

This mirrors what many labs experience when switching from spreadsheets or legacy platforms.

ASTM C39 compressive strength testing is foundational to concrete quality assurance, but the workflows supporting it do not need to be manual or fragmented.

By connecting field sampling, cylinder tracking, break testing, and reporting into a single system, modern concrete testing software helps CMT labs improve accuracy, speed, and compliance without adding complexity.

As firms look to modernize their ASTM workflows, C39 is often the most impactful place to start.

Explore the evolution of ASTM geotechnical standards and how digital workflows, LIMS software, and automation are shaping the future of ASTM...

Learn how construction materials testing labs can balance ASTM compliance with digital innovation to improve efficiency, accuracy, and audit...

Aldoa announces its integration with ForneyVault, creating a seamless data flow between field collection, lab testing, and reporting for construction...

Purpose-built for consultants and engineers. The easy-to-use system helps your team complete projects on time, stay within budget, and increase profitability.