The Future of Field Data Collection and AI-Powered Report Writing in Engineering

Discover how AI-powered field data collection and report writing are transforming engineering firms. Learn best practices, reduce manual entry, and...

Construction materials testing (CMT) laboratories operate in a highly regulated environment where accuracy, traceability, and documentation are mandatory. Whether testing concrete strength, soil compaction, or asphalt performance, compliance with ASTM, AASHTO, and ISO 17025 standards is non-negotiable.

As testing volumes increase and audits become more stringent, many labs struggle with manual paperwork, fragmented spreadsheets, and disconnected systems. These workflows make it difficult to maintain consistency, prove compliance, and prepare for audits efficiently.

A Laboratory Information Management System (LIMS) designed for construction materials testing provides system-level controls that help labs meet ASTM and AASHTO requirements while reducing administrative overhead. This article explains how LIMS software supports compliance and why it plays a critical role in modern CMT lab operations.

👉 For a broader overview of LIMS platforms built for this industry, see our guide to the best LIMS for geotechnical and construction materials testing labs.

Before examining how LIMS software supports compliance, it is important to understand the role of each standard in construction materials testing.

Defines standardized test methods for construction materials such as concrete, soils, aggregates, and asphalt. Examples include ASTM C39 for concrete compressive strength and ASTM D1557 for soil compaction.

Establishes specifications and test methods primarily for transportation and highway materials. Many DOT projects require strict adherence to AASHTO procedures.

Defines quality management and technical competency requirements for testing laboratories. Accreditation under ISO 17025 requires strong traceability, documentation, and audit readiness.

LIMS software supports compliance by embedding these standards directly into daily lab workflows rather than relying on manual enforcement.

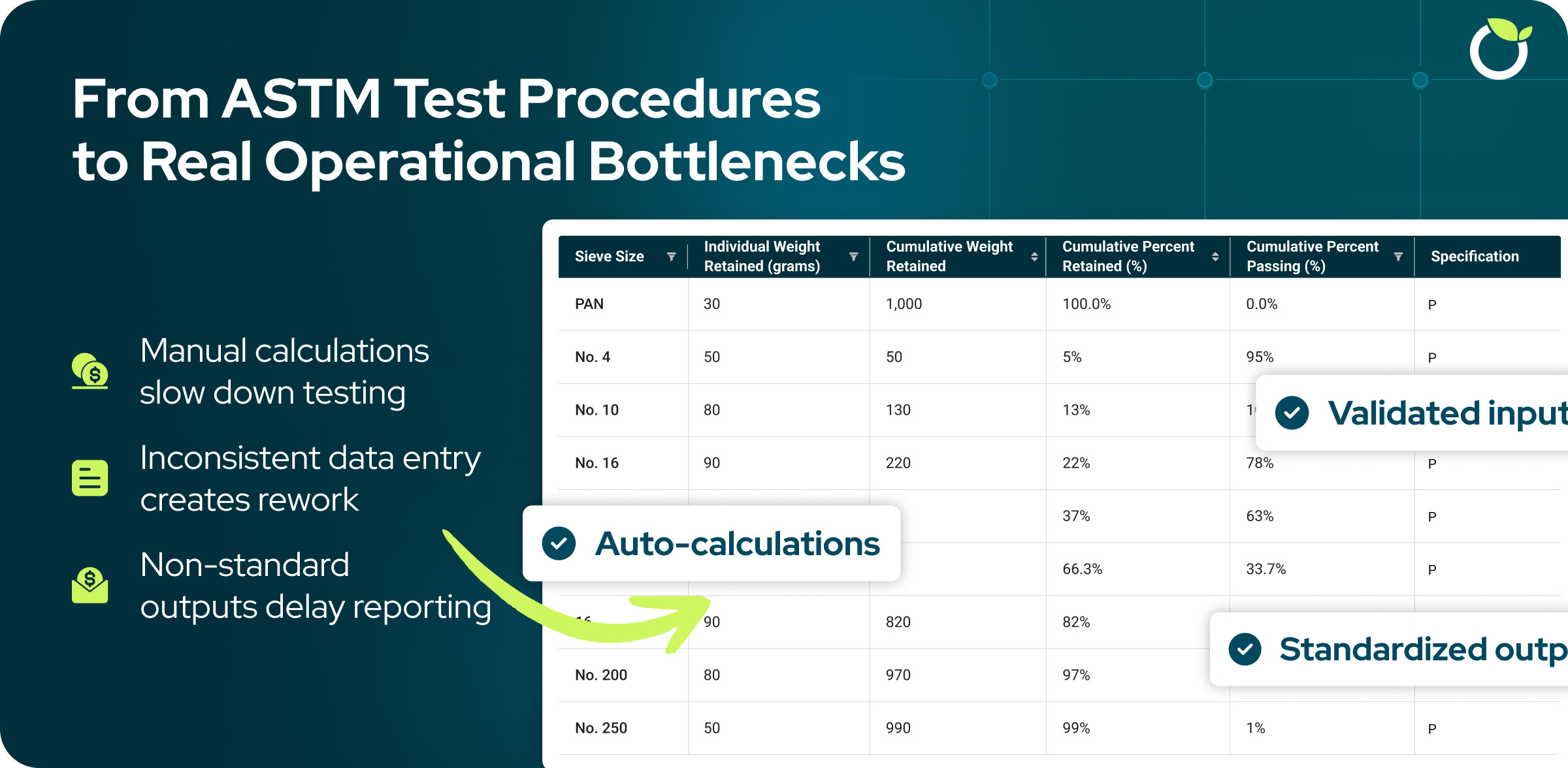

Without a LIMS, compliance can be time-consuming, inconsistent, and error-prone. Common challenges include:

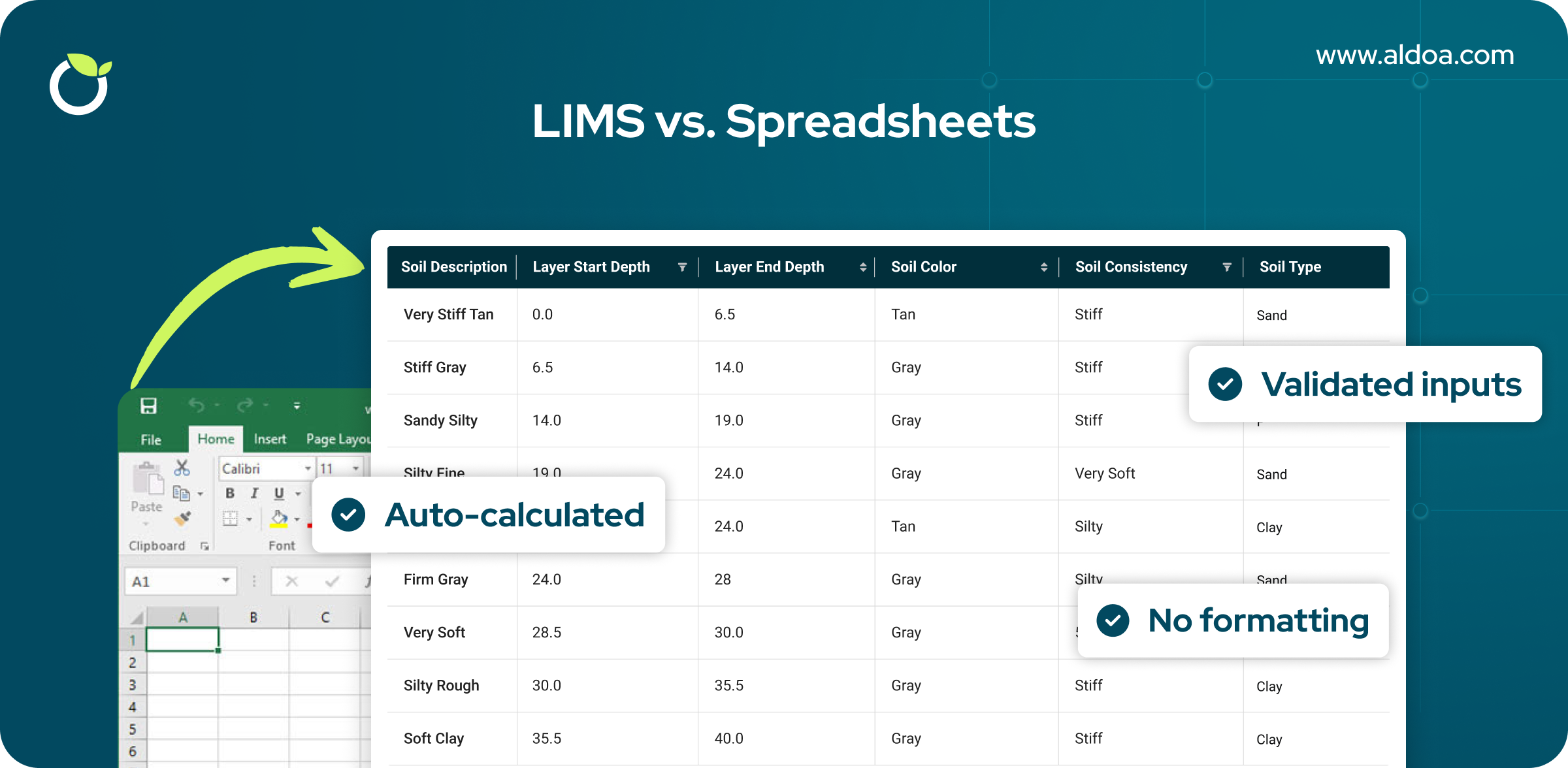

Many of these challenges are amplified when labs rely heavily on spreadsheets or paper records to manage testing data and documentation. The challenge isn’t just documenting ASTM tests. It’s how manual steps inside each test introduce operational bottlenecks that slow teams down and increase compliance risk.

👉 For a detailed breakdown of why spreadsheets fail at scale, read our article on LIMS vs spreadsheets for materials testing labs.

.png?width=2400&height=1176&name=3.%20Manual%20vs%20Automated%20Steps%20Comparison%20(2).png)

A LIMS is much more than a digital database. It’s an integrated workflow engine that enforces standards, tracks data lineage, and automates documentation.

In traditional lab setups, ASTM compliance relies on manual checks at every stage: sampling, calculations, and reporting. Each handoff introduces risk. A compliance-ready LIMS removes that friction by standardizing and automating each step, from field data capture to final ASTM-compliant reports.

Pre-configured test templates aligned with ASTM and AASHTO methods ensure:

This reduces variation between technicians and ensures consistent compliance across projects.

LIMS software creates a complete digital record of:

This level of traceability is essential for ISO 17025 audits and DOT inspections.

A compliance-ready LIMS allows labs to:

This eliminates one of the most common audit findings.

From field collection to lab analysis, every sample is:

This ensures defensible data lineage for ASTM and AASHTO requirements.

With a LIMS, labs can:

Audits shift from reactive document hunting to structured review.

Digitizing ASTM testing workflows doesn’t just improve compliance on paper. It changes how every role across a construction materials testing organization works day to day. From the field to the lab to leadership, standardized digital workflows reduce friction, improve accountability, and scale consistency.

Digitizing ASTM testing workflows improves accuracy, accountability, and efficiency for every role involved in construction materials testing.

For field staff, ASTM compliance often breaks down at the point of data capture. Paper forms, handwritten notes, and unclear requirements lead to missing information and rework.

Digitized workflows help field technicians by:

The result is less guesswork, fewer callbacks, and more confidence that data is collected correctly the first time.

Lab managers are responsible for ensuring that every test follows ASTM procedures, regardless of who performs it. Manual oversight does not scale as volume increases.

Digitized ASTM workflows allow lab managers to:

Instead of policing compliance, managers can focus on quality control and operational efficiency.

Project managers feel the downstream effects of compliance issues through delayed reports, client questions, and change orders. Digitization creates visibility across the entire testing lifecycle.

With digital ASTM workflows, project managers gain:

This improves client communication and keeps projects moving without disruption.

At the leadership level, ASTM compliance is about risk management, reputation, and scalability. Manual systems introduce hidden risk that grows with volume.

Digitizing ASTM workflows helps firm leaders:

Compliance becomes a built-in operational capability rather than a constant concern.

With a modern LIMS in place, auditors can review standardized digital records, complete audit trails, and calibration histories without delays. What once required days or weeks of preparation can often be completed in hours.

Without a LIMS:

With a LIMS:

What used to take days or weeks now takes hours or less.

To get the most out of your system:

Choosing industry-specific software is critical. Generic LIMS platforms often require extensive customization and still fall short for CMT workflows. Purpose-built systems designed specifically for construction materials testing perform best.

👉 Our comparison of leading platforms highlights these differences in detail. See how vendors stack up when you compare LIMS software for geotechnical labs.

Work with your vendor to preload ASTM, AASHTO, and ISO-compliant templates specific to your lab's services.

Ensure everyone—from field techs to lab analysts—knows how to use:

Conduct mock audits using your LIMS to identify gaps or outdated practices before the real inspection happens.

Maintaining ASTM, AASHTO, and ISO 17025 compliance is no longer just a documentation challenge. It is a workflow challenge. Modern construction materials testing labs need systems that enforce standards automatically, maintain traceability, and simplify audits.

A LIMS built specifically for CMT and geotechnical workflows transforms compliance from a manual burden into a repeatable, defensible process. By embedding standards into daily operations, labs reduce risk, improve consistency, and gain confidence during audits.

👉 If you are evaluating compliance-ready systems, start with our guide to the best LIMS for geotechnical and construction materials testing labs, then see how Aldoa modernizes compliance end to end.

Schedule a demo of Aldoa’s LIMS platform and see how it helps construction materials testing labs like yours stay compliant—without the stress.

Discover how AI-powered field data collection and report writing are transforming engineering firms. Learn best practices, reduce manual entry, and...

Discover the best project management software built for consulting firms. Learn essential features, compare leading solutions, and find the perfect...

Discover proven strategies and tools to boost engineering firm efficiency. Learn how to streamline project management, resource planning, and field...

Purpose-built for consultants and engineers. The easy-to-use system helps your team complete projects on time, stay within budget, and increase profitability.